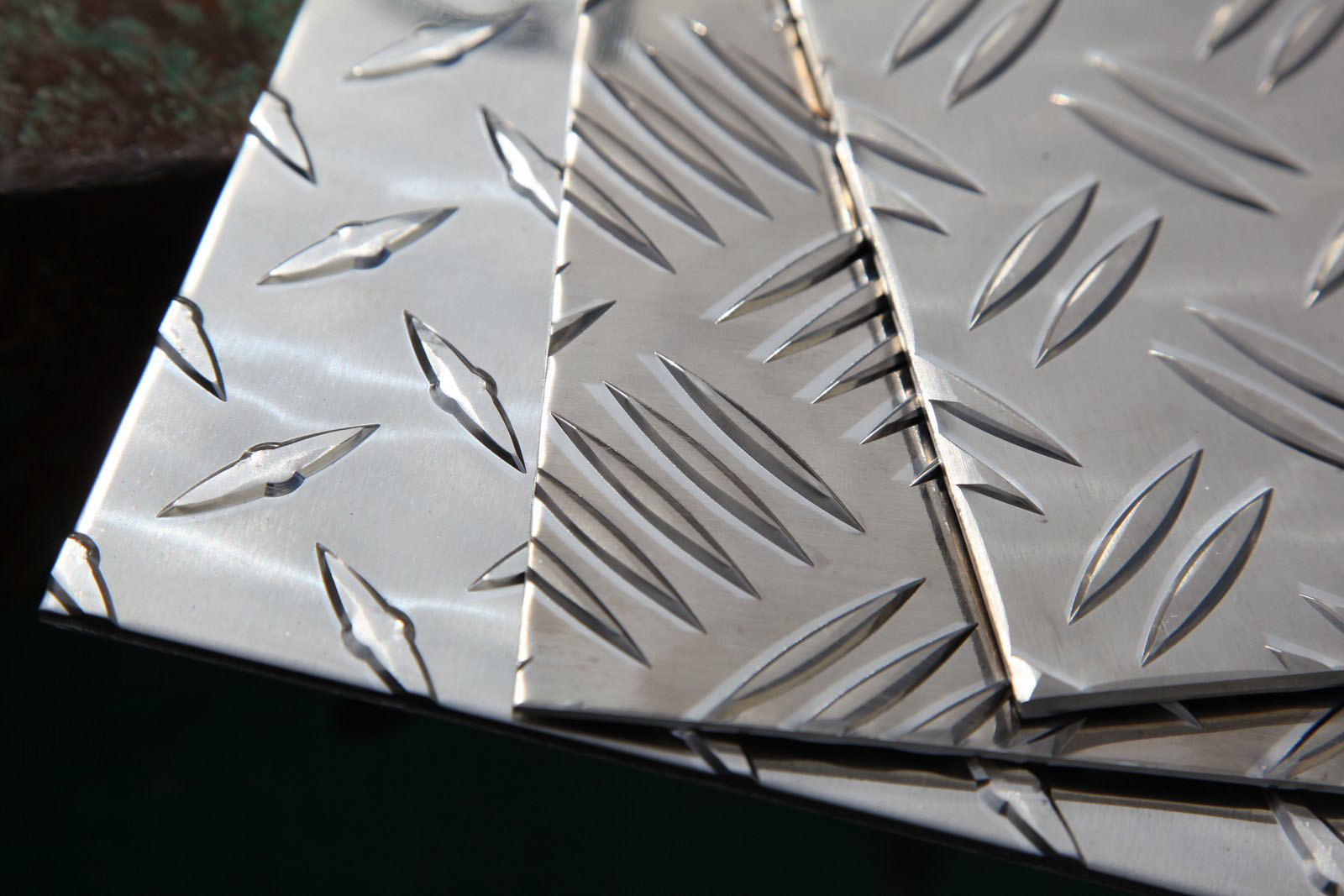

A brilliant surface, narrow tolerances, and customizable dimensions are Impol’s advantages regarding tread plates. Their mechanical properties are adapted to the customer’s requirements and comply with the EN, CE, and ASTM international standards. Given the customer’s wishes, Impol’s tread plates can also be subject to further bending and cutting treatment or applied for decorative purposes.

Properties

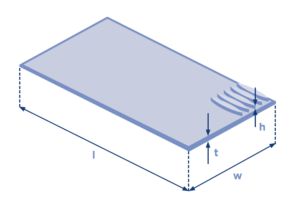

Tread plates are manufactured from selected 1000, 3000, and 5000 series alloys. The tread plate can be soft, semi-hard, and hard; the surface can also include five bar (Quintet), two bar (Duet), and diamond (Diamond) patterns. In addition, Impol can produce tread plates with standard dimensions, usually in stock, or tread plates customized to the customer’s dimensions with more stringent tolerances than the one listed in the standard in question.

Intended uses

Technological manufacturing process

Compliance

with international standards

- EN 573-3 Aluminium and aluminium alloys – Chemical composition and form of wrought products

- EN 1386 Aluminium and aluminium alloys – Sheets with embossed patterns – Specifications

- EN 15088 Aluminium and aluminium alloys – Structural products for construction work