Adapting to the customers’ needs

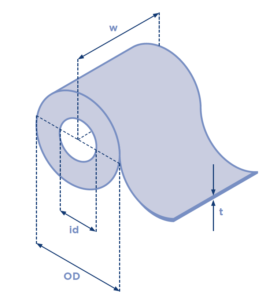

Impol produces a wide range of strips that can be applied in all technical, transport, construction, electrotechnology, household, and other branches. The technology and equipment allow us to consider the customers’ wishes and needs during production. Thus, strips are produced to the desired length, width, and external and internal diameter. By combining the chemical composition and applying controlled hot and cold working, Impol can attain standards and specific properties and qualities of cold-rolled strips. And by acquiring new knowledge, Impol can constantly develop new products and improve the properties of the current ones. Impol provides both mill finish and embossed surface tension leveling or PVC-foil coating. Selected alloy and temper combinations can also be supplied on cardboard cores.

Properties

- 1000 series alloys are characterized by their corrosion resistance, good formability, weldability, and conductivity.

- 3000 series alloys are characterized by their excellent resistance to atmospheric and chemical agents, higher mechanical properties than pure aluminium, and good formability.

- 5000 series alloys are determined by their moderate to high strength, excellent chemical durability, excellent formability, and good polishability.

- 8000 series alloys have high formability, with deep drawing formability standing out the most.

Soft, quarter-hard, half-hard, three-quarter-hard, hard and full hard tempers can be provided. Deep drawing ability is available by certain alloy and temper combinations.

Strip surface can be subject to mill finish, painted or embossed with various patterns.

Intended uses

Technological manufacturing process

Strips are manufactured from rolling slabs subject to hot-rolling to the desired thickness. Cooling is followed by cold rolling supported by additional operations such as in-process annealing and trimming. Cold rolling until the final thickness is attained is followed by tension leveling, surface embossing, cutting, and final annealing. These combined operations provide the desired final strip shape, prescribed dimensions, and quality.

Compliance

with international standards

- EN 573-3 Aluminium and aluminium alloys – Chemical composition and form of wrought products

- EN 485-2 Aluminium and aluminium alloys – Sheet, strip and plate

- EN 485-4 Aluminium and aluminium alloys – Sheet, strip and plate

- EN 15088 Aluminium and aluminium alloys – Structural products for construction work – Technical conditions for inspection and delivery