Unique properties and a wide range of applications.

Aluminium foil is an indispensable part of many consumer products. Its use is so widespread that it falls among essential cold-rolled aluminium and aluminium alloy products. It is an environmentally-friendly product that may be recycled and reused and is also incredibly beneficial. The low price and unique combination of properties also speak volumes about its advantages.

Aluminium foil properties:

- Leakproofness: the aluminium crystal structure equips foil with high leakproofness and complete light protection.

- Non-toxicity: aluminium foil is not toxic.

- Corrosion resistance: aluminium foil has excellent corrosion resistance and reacts only to highly acidic and alkaline substances.

- Non-absorbency: aluminium foil does not absorb liquids and is also oil resistant.

- Hygiene and safety: aluminium foil is sterile.

- Smell and taste: aluminium foil is odorless and tasteless.

- Shape preservation: soft temper foil provides a high ability to preserve shape.

- Recycling: aluminium can be recycled multiple times without losing its quality.

Intended uses

Technological production process

Foils produced in such a manner are either single or doubled, which means that two foils are rolled simultaneously. The outer sides in contact with working rolls are bright, whereas the inner sides where the two foils are in contact remain matt. The doubled foil rolling procedure is applied to all foils with a final thickness of 0,050 mm or less.

1. Cold rolling

Cold-rolling on state-of-the-art four-high rolling mills constitutes an essential part of the production process.

2. Cutting and annealing

Cutting and annealing both help attain the desired final aluminium foil properties and remove residues of rolling oils from the surface.

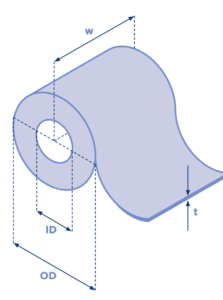

3. Striping onto the core

Following final trimming and cutting, foil is striped to the desired external diameter or in the desired length on steel or aluminium cores, depending on the customer’s requirements.

Compliance

with international standards:

- EN 573-3 Aluminium and aluminium alloys – Chemical composition and form of wrought products

- EN 546-2 Aluminium and aluminium alloys – Foil

- EN 546-3 Aluminium and aluminium alloys – Foil

- EN 546-4 Aluminium and aluminium alloys – Foil

- EN 683-2 Aluminium and aluminium alloys – Cold-rolled semi-finished products for heat converters

- EN 683-3 Aluminium and aluminium alloys – Cold-rolled semi-finished products for heat converters

- EN 602 Aluminium and aluminium alloys -Wrought products -Chemical composition of semi-finished products used for the fabrication of articles for use in contact with foodstuff