With criteria of the highest quality

Technical perfection, high-quality standards, and top production equipment are just three aspects of producing aluminium extruded products. In addition, special alloys are developed together with our customers through constant development and cooperation with casting experts, allowing for above-standard mechanical properties. At the same time, we recently managed to further increase the quality of the production equipment and volume. This enables us to take large orders from renowned automotive, aerospace, and space industry customers and provide short delivery periods.

Extrusion, drawing, and heat treatment procedures

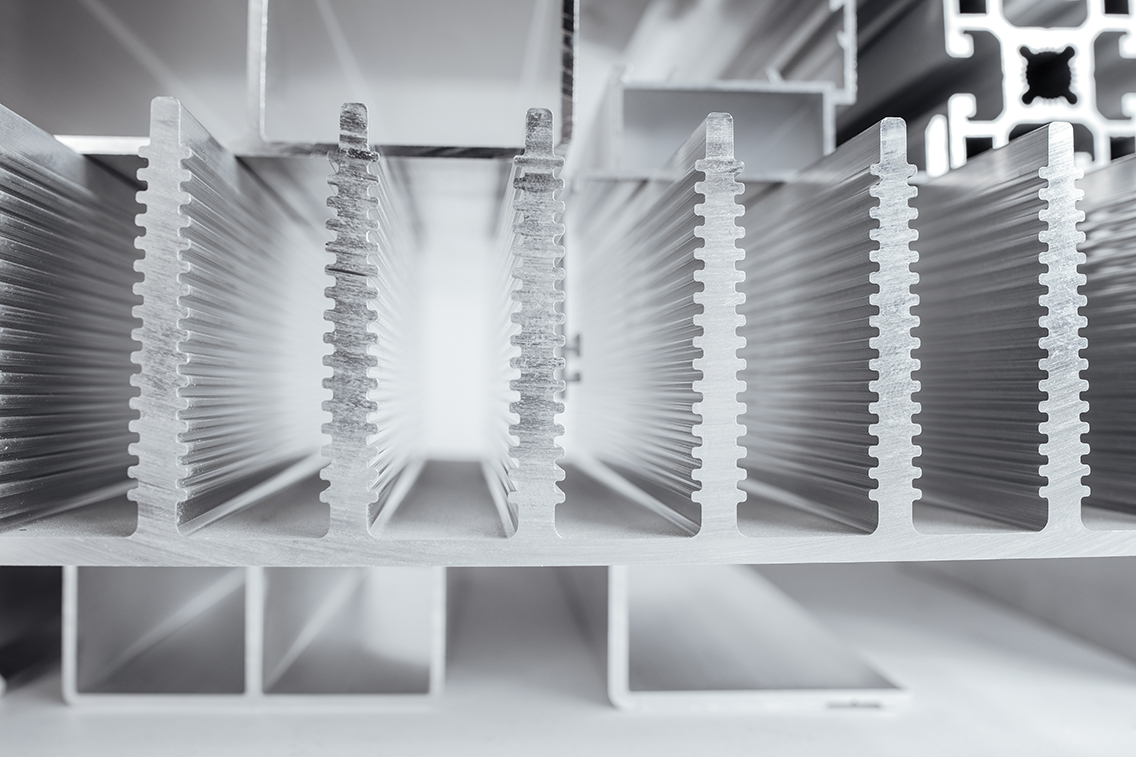

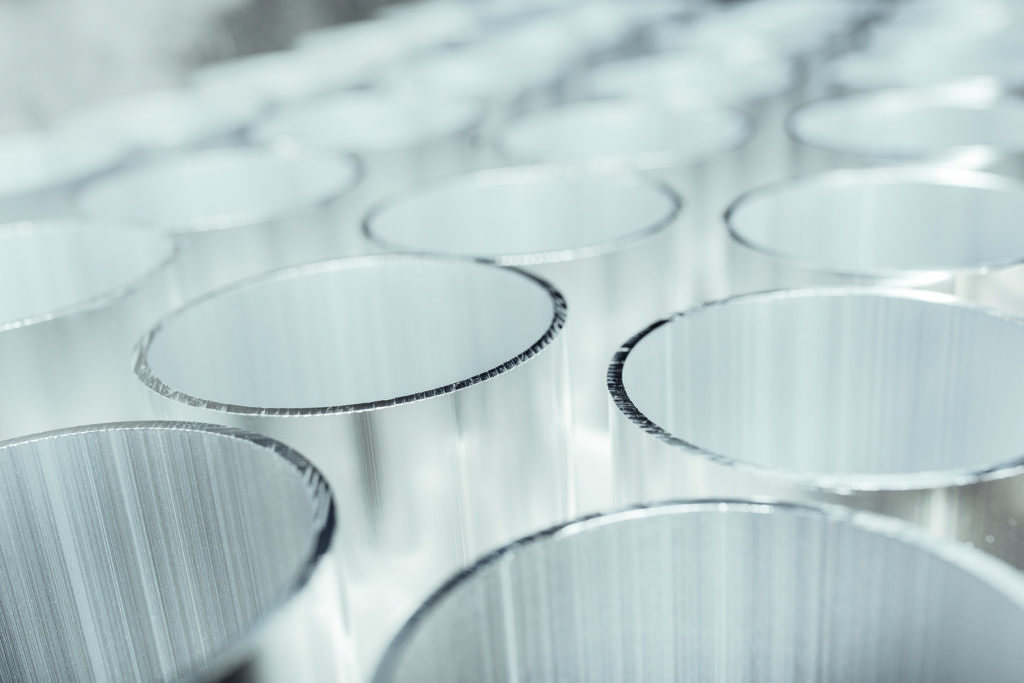

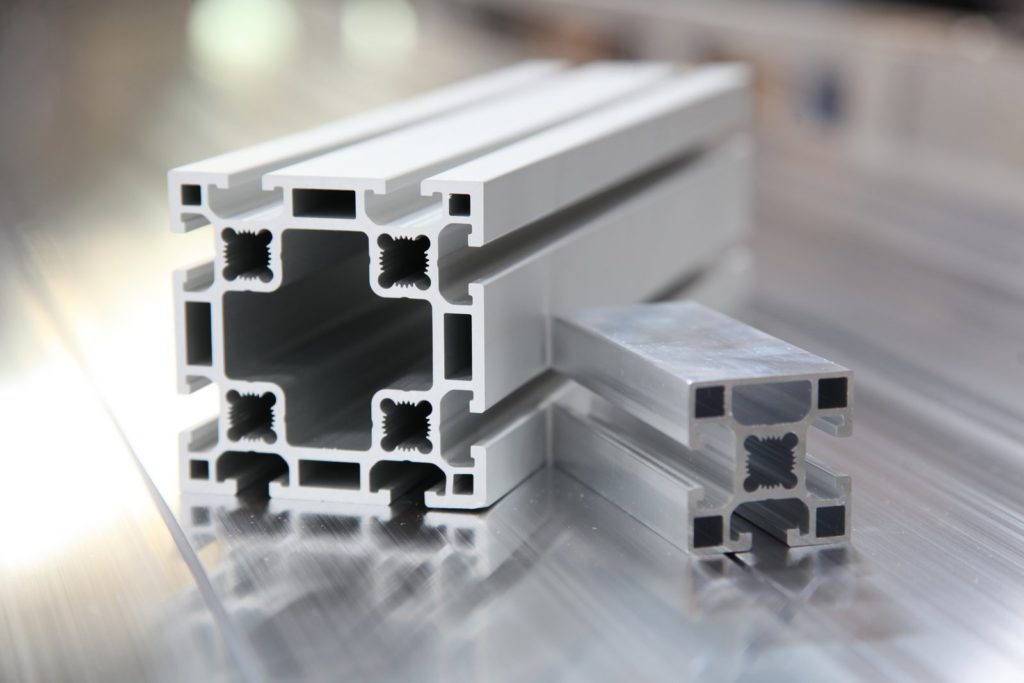

We carry out various production processes depending on the intended use. Hot extrusion is a process during which the heated material (log) is heated to a temperature about 10 °C below the solidus temperature. The material for extrusion is 100 % automatically controlled using an ultrasonic device that facilitates ultrasonic control of billets in compliance with the AMS-MIL-STD-2154, Class B and A, and ASTM B594, Class B, and A standards. Logs are extruded using a hydraulic extrusion press through a steel matrix. The dimensions and shape of the product depend on the shape of the matrix aperture. Extrusion is conducted by two procedures, namely direct and indirect extrusion. The procedure sees the application of various instruments (matrices) that may be either flat or contain a pre-chamber, which applies to bars in particular. In contrast, hollow profiles and sections see the application of porthole dies, by which seamed products are extruded. Seamless products (tubes and pipes) are extruded by a mandrel.

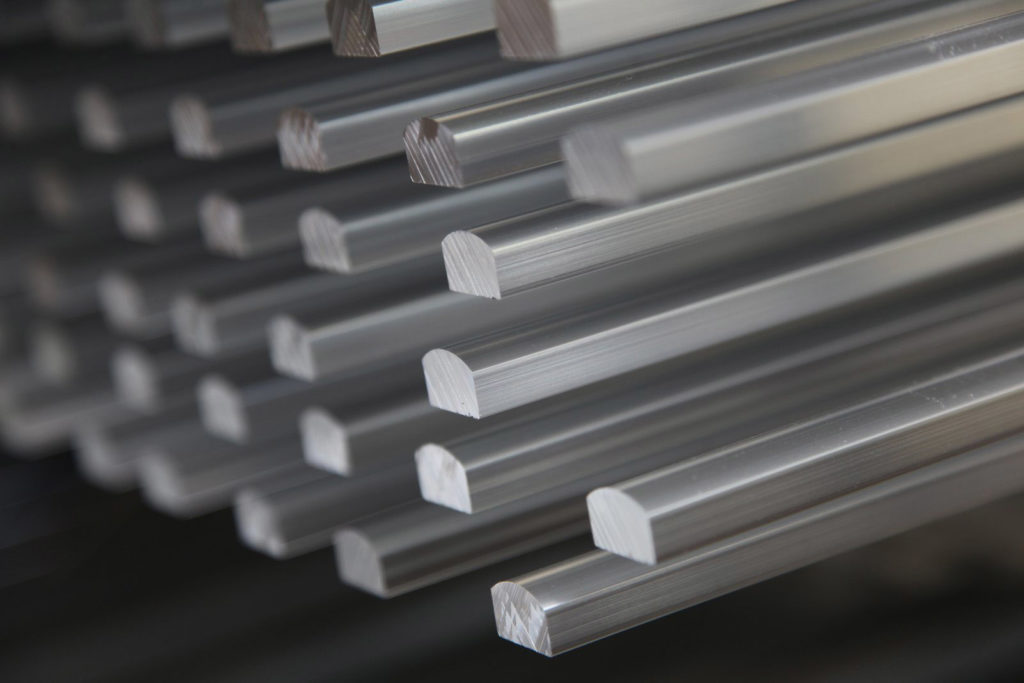

The rods, bars and tubes, profile, and section production process encompasses operations that ensure high-quality, heat-treated products: homogenization and grinding, heating and extrusion on state-of-the-art presses, cold and hot working, and strengthening and cutting to length.

The production process includes various direct extrusion presses whose rated output amounts to 12 to 55 MN and one indirect extrusion press whose rated output amounts to 35 MN. The following dimensions can be extruded: 8 to 180 mm for rods and a maximum of 320 mm for profiles and sections with a circumcircle.

Cold working (drawing) of products takes place on standard drawing machines and continuous drawing lines (drawing, straightening, cutting to length). Impol produces extruded and drawn rods, bars and tubes, profiles and sections in all standard dimensions in compliance with international standards.

Special attention is paid to stress-free states of materials, free-cutting alloys (machining), and rods for forging. Products can be 100% ultrasonically controlled at the customer’s request after completing the production process.

Alloy groups

The products mentioned above are produced from alloys divided into two groups: free-cutting alloys and groups of other aluminium alloys.

Approved specifications

- Mercedes-Benz DBL 4919.10, .20, .30

- Volkswagen TL 116-N/C-20, N/C-24

- BMW GS 93047 (AlMgSi-STD, AlMgSi-CRA, AlMgSi-HST, AlMgSi-CHA, AlMgSi-CHF)

Tables of properties:

FREE-CUTTING ALLOYS

RoHS 12002/95/EC From July 2006 |

RoHS 22011/65/EU From January 2013 |

RoHS 32018/740/EU From June 2021 |

|

| Max. 0.60 % Pb | Max. 0.40 % Pb

|

Max. 0.10 % Pb

|

|

| EN AW 2011 | EN AW 2011 RoHS | 2011 LF | with Bi |

| AA 2041 | |||

| EN AW 6262 | EN AW 6026 | EN AW 6026 LF | with Bi |

| EN AW 6064A | EN AW 6262 A | with Sn and Bi | |

| EN AW 6012 | EN AW 6023 | with Sn and Bi | |

| AA 6028 | with Sn and Bi | ||

| EN AW 2007* | AA 2028 A | 2030 LF | with Bi |

| EN AW 2030* | AA 2044 | with Sn and Bi | |

| EN AW 2033 |

ELV conform, Pb max. 1.00 %

ALUMINIUM ALLOY GROUPS

| ASTM / EN | IMPOL | DESCRIPTION | |

| (ASTM – 1xxx) | “A” | group 1 – aluminium | |

| (ASTM – 3xxx) | “M” | group 2 – alumans | |

| (ASTM – 5xxx) | “P” | group 3 – perals | |

| (ASTM – 6xxx) | “AC” | group 4 – anticorodals | |

| (ASTM – 2xxx) | “D” | group 5 – durals | |

| (ASTM – 7xxx) | “PD” | group 6 – perdurals | |

| (ASTM – 4xxx) | “AS” | group 7 – silumins | |

Products are produced according to their intended use by means of extrusion, drawing, and heat treatment. The standards mentioned above apply to these treatment methods as well. Products can also be provided in compliance with other standards or upon agreement with the customer.