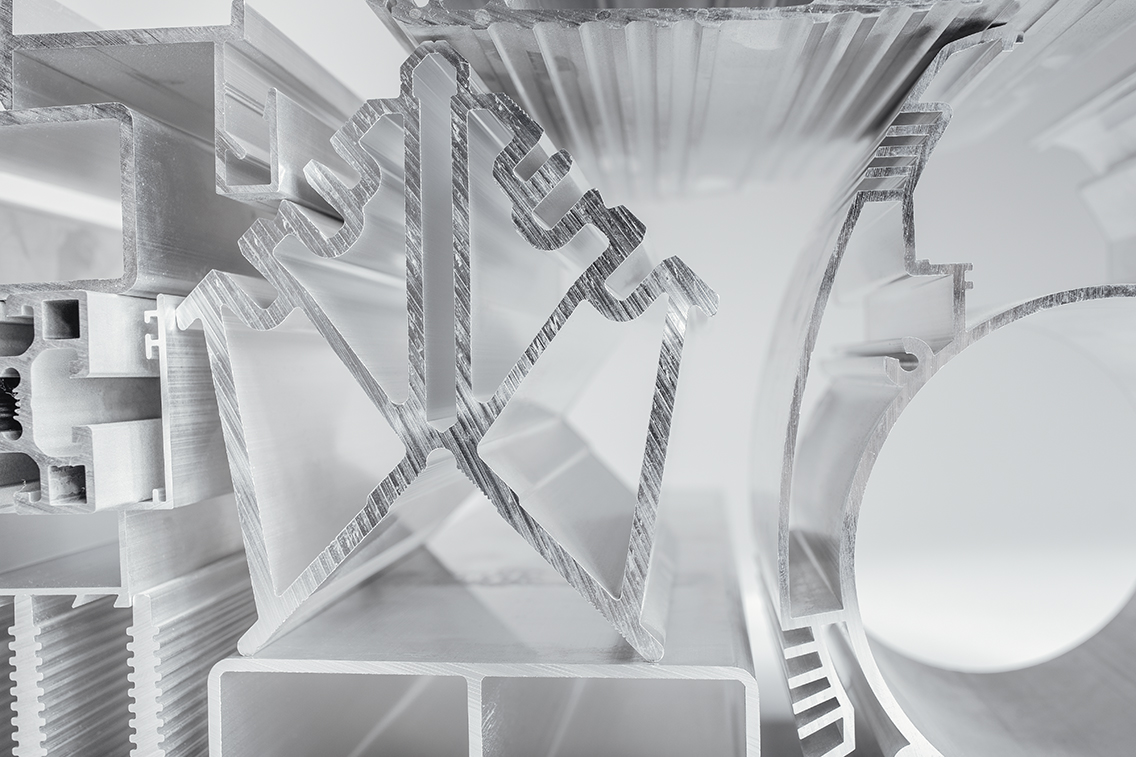

Aluminum extrusions are an essential part of our homes, although many people do not even notice them. They are usually part of window or door systems, but the application does not stop there. Aluminum bars have countless applications in building and manufacturing industries, therefore the quality of each product must be impeccable.

Impol is the largest European supplier of aluminum extruded bars for forging and one of the largest suppliers of drawn bars in Europe and the US. In our manufacturing process, which is trusted by all the largest European automotive companies and the European aviation industry, we apply the best possible production practices which we continuously improve. Read on to find out why this process is crucial for so many industries and why Impol is the best answer when it comes to quality extrusion rods, tubes, profiles …

Aluminum Extrusion Basics

Extrusion is a modern process in which aluminum billets are heated and pushed through a shaped die opening. The opening can be modified to create different shapes and sizes to fulfill a user’s specific needs.

Depending on the required aluminum bar type, we use different steel dies.

- For solid bars or profiles

- flat dies

- pre-chamber dies

- For hollow bars or profiles

- chamber dies

You can read more about the differences in the extrusion process and the created products on our website.

The 6 Steps of Aluminum Extrusion

The extrusion process is carried out in direct or indirect extrusion presses with different power levels (at Impol, those are between 12.5 and 55-MN). The basic process can be broken down into six distinct steps, although they can be modified or expanded upon depending on the customer’s specific requirements.

But even before the extrusion process begins, the cast aluminum rods needs to be cut into smaller pieces. These short pieces are called billets. The pre-cut billets ensure that the length of each extruded bar will be roughly the same and there will be no material wastage.

Step 1: Preheating the aluminum billet and steel die to a specified temperature

- The billets are heated in induction or gas furnaces from room temperature to the extrusion The temperature varies depending on the alloy and the final temper.

- The heated billets need to be malleable enough to take on the required shape, but still firm enough to retain their shape during transportation.

- The push bat starts applying pressure into the heated billet and pushes it towards the die opening.

Step 2: Loading the billet into the steel extrusion press container

- To prevent heat loss, the billets are quickly transported from the furnace into the press. They are loaded into the recipient and are ready to be extruded.

- The ram starts applying pressure into the heated billet and pushes it towards the die opening.

Step 3: Extrusion

- The heated aluminum billet is pushed through the openings in the tool. Those openings can be modified to create different shapes and sizes. The process is similar to a cookie press, where the different shaped discs create different cookie designs.

- When the bars exit the press, they are already extruded to their required shape.

Step 4: Controlled cooling

- The extrusion process is followed by quick cooling of the extruded bars/tubes/profile

- When exiting the press, the fully formed bars/profiles are pushed through a water bath which guarantees uniform quenching of the heated aluminum.

- The quenching process is necessary to ensure the required mechanical properties and adequate material microstructure.

- To prevent any material deformation, the cooling process must be carried out without delays immediately after the extrusion process.

Step 5: Stretching

- Immediately after quenching, the extruded bars are cut into the prescribed interphase length.

- The cut bars are then grabbed by a puller, which lays them over the runout table. This allows them to further cool down.

- In this phase, the extruded bars are run through a strengthening process, which stretches the bars and ensures their mechanical properties by removing the internal tension within the bars.

Step 6: Cutting and final packaging

- The quenched and straightened bars are cut to the length specified by the customer.

- At this stage, the aluminum bars have the properties of the T1/T4 temper. To ensure better mechanical properties of the T5/T6/T66 temper, the bars are artificially aged.

- The aging process further strengthens the extruded profiles and ensures they fulfill the mechanical properties specified for individual alloys.

Which Factors Affect Extrusion?

While the above-described steps of the extrusion process may seem fairly simple and automatized, they are anything but. In truth, extrusion is a very complex process which is dependent on the correlation between numerous parameters that need to be adapted during the process. Those parameters are called TST parameters and refer to the temperature, speed and time.

In essence, before, during and after extrusion, the following factors must be closely monitored:

- Billet temperature in heating furnaces

- container temperature

- tool temperature

- exit temperature of the aluminium bar/profile

- quench media temperature

- extrusion rate and quench delay

- extrusion speed

- final products and tool dimensions

These parameters must be closely controlled and monitored. The most important among them is temperature, which needs to be adapted depending on the extruded material and the desired final shape of the product. In general, the aluminum alloy billets need to be heated to between 300 and 595°C.

Another very important part of the extrusion process is quenching. As seen above, the extruded profiles are quenched immediately after exiting the die. In this stage it is essential that every part of the aluminum bar is covered by the right amount of water for the right amount of time. Meaning that they cool down from the extrusion temperature to room temperature as quickly as possible. Only then can the extruded bars/tubes/profiles be cooled uniformly and reach the highest mechanical and technological properties. The fastest quenching rate will achieve the best combination of strength, toughness and microstructure. This process is commonly used in producing extruded shapes of the 6xxx Al series e.g the T66 temper.

After the extrusion and quenching process is completed successfully, the following parameters need to be monitored closely:

- dimensions and tolerances of the product

- surface finish

- mechanical properties

- macrostructure of the bars/profiles/tubes (without back end defects)

- other special quality considerations

Advantages of Aluminum Extrusion

In comparison to other products, aluminum extrusions are the preferential option due to their unique combination of lightness and toughness. From the industry viewpoint, aluminum extrusion has additional advantages:

- They are generally a competitive and economical production option especially when dealing with very complex cross-sections.

- They are stronger and tough

- The surface finish of extruded products is impeccable and in general, those products are stronger when compared to aluminum castings.

Despite the numerous advantages, there is also an important disadvantage to aluminum extrusions in comparison to casting. And that is their size. Aluminum extrusions are limited by the size of both the billet and the capacity of the steel container on the extrusion press.

Different Extrusion Types

In hot extrusion, there are to different extrusion processes:

- direct extrusion

- indirect extrusion

Direct extrusion

Direct extrusion is the simplest production mode. This method is most commonly used to produce aluminum extrusions. In it, the die is stationary while the ram forces the billet through the die opening. The action of the billet and ram moving forward in the same direction has led to this method being called the forward or direct aluminum extrusion process.

Indirect extrusion

Indirect extrusion is a process in which the billet remains stationary, but the assembly on the end of the ram moves against the billet. This creates the pressure necessary for metal to flow through the die.

This is the main advantage of the indirect press as it enables the pressing of harder alloys (2xxx, 7xxx) and products with smaller cross-sections due to the smaller extrusion pressures. Lower pressures also allow for lower pressing temperatures and consequently greater extrusion speed. This of course increases productivity.

What Shapes can be Extruded?

Extrusion is a part of so many industries that it is not possible to create a complete list of every one of its types. There are limitless possibilities regarding shapes which are available in a wide range of configurations and sizes. The main categories are:

- Solid shapes: solid bars and rods with various cross-sections (e.g. circles, rectangles, squares, etc.)

- Semi-solid shapes:such as angles, channels, and other partially open forms

- Hollow shapes: tubes or profiles with various cross-sections (e.g. circles, rectangles, squares, etc.)

Extruded Billets as a Semi-finished Product

Especially in large and complex industries, the extruded bars are sometimes not suitable to be used as finished products due to their wider tolerances, worse straightness and greater surface roughness. For such demanding industries, drawn products are more suitable, as the tolerances are significantly more rigorous and the surface is smoother. Drawn products allow customers to achieve greater productivity, less work operations and a smaller scrap share.

In comparison to extrusion, drawing is a cold manufacturing process that forms aluminum bars by reducing their cross-section. This is accomplished by pulling the bar/tube through a smaller die. Although the process is similar to extrusion, the direction of the applied force is different. In extrusion, the billet is pushed through the die opening, where in drawing it is pulled through.

The drawing process has many important factors that affect the quality and precision of formed bars or tubes, such as die angle, drawing speed, lubrication condition and pass reduction ratio.

For cases of extremely complex final products or thinner products, the extruded products are replaced by rolled products or by mechanical processing or forging simpler extruded products (flat, square or hexagonal bar). This is how we can ensure products of more challenging shapes or with more precise dimensions.

If you have any additional questions about our services or processes, you can visit our website for more information or contact us.

Author: M.Sc. Ervin Rošer, process engineer