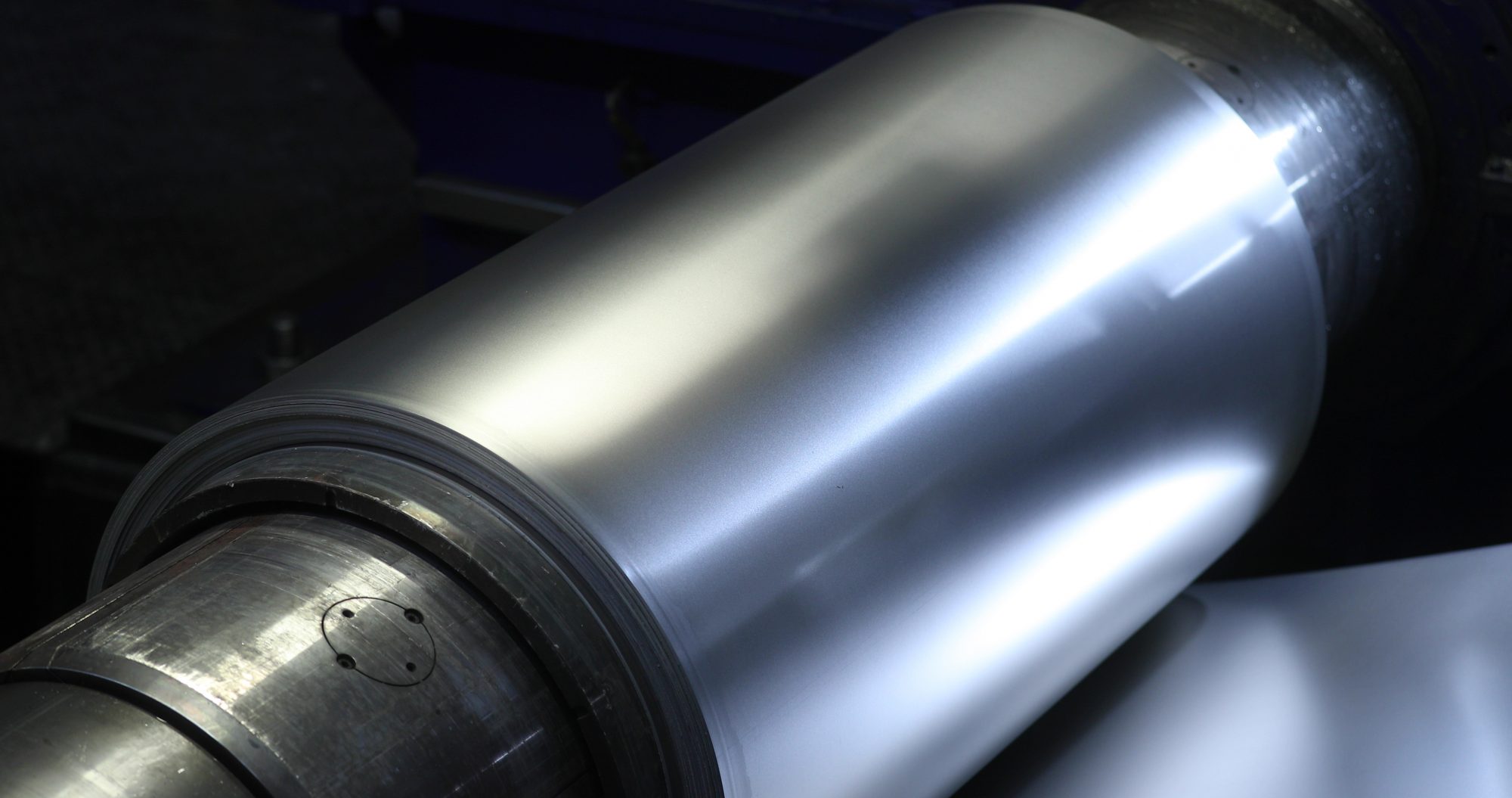

With the Electrical discharge texturing state-of-the-art technology we are ensuring the durability and appropriate topography of the surface of strips on exposed parts intended for the automotive industry

At the Impol Group we are constantly adapting to the needs of our customers. Last year, we developed a new product – EDT strips – for the needs of our clients in the automotive industry. These strips have a special isotropic surface topography, enabling better and unconditional forming properties and a uniform appearance of the surface, particularly after painting, explained Bojan Kropf, Technical Director of the Rolling Division.

Achieving quality and productivity

The term EDT (Electro Discharge Texturing) means generating texture by discharging electric charges on the roller’s surface. It is a special procedure of preparing the working rollers with which the aluminium strip comes into contact during the cold-rolling procedure, which is known as the EDT transition. Using various electrode materials we can achieve a different polarity and surface roughness along the entire length of the roller. At the same time, we can use this technology to pursue two important objectives: achieving better product quality and higher productivity.

Advantages

Better formability of the aluminium strip and improved appearance of the paint are significant advantages of EDT strips for our clients. An additional advantage of the surface processed in this manner (compared to the “Mill Finish” surface) is also a low and constant friction coefficient during rolling, and at the same time the lubricating wells increase the hydrostatic pressure during subsequent forming by the client. This results in the production of high-quality strips.

Additional procedures of preparing working rollers: chrome plating and “superfinish”

In addition to mechanical properties of the strip, such as strength and ductility, the EDT procedure is also used for processing the roller’s surface through texturing and “freezing” with subsequent chrome-plating in order to further process the strip due to the direct contact between the working roller and the strip. The chrome layer increases service life and thermal conductivity, and reduces the wear of the roller. In addition to chrome plating, the tops of the rough surface may be removed after the EDT procedure by further polishing the rollers using polishing paper. With the additional “superfinish” grinding procedure the portion of the contact surface between the roller and the strip is increased along with the roller’s service life.