Flying on the wings of exceptional properties

There is no room for compromise in the aeronautical and aerospace industry – every component must meet the most demanding standards. Aluminium’s unique combination of light weight and exceptional durability makes it an indispensable material in this field.

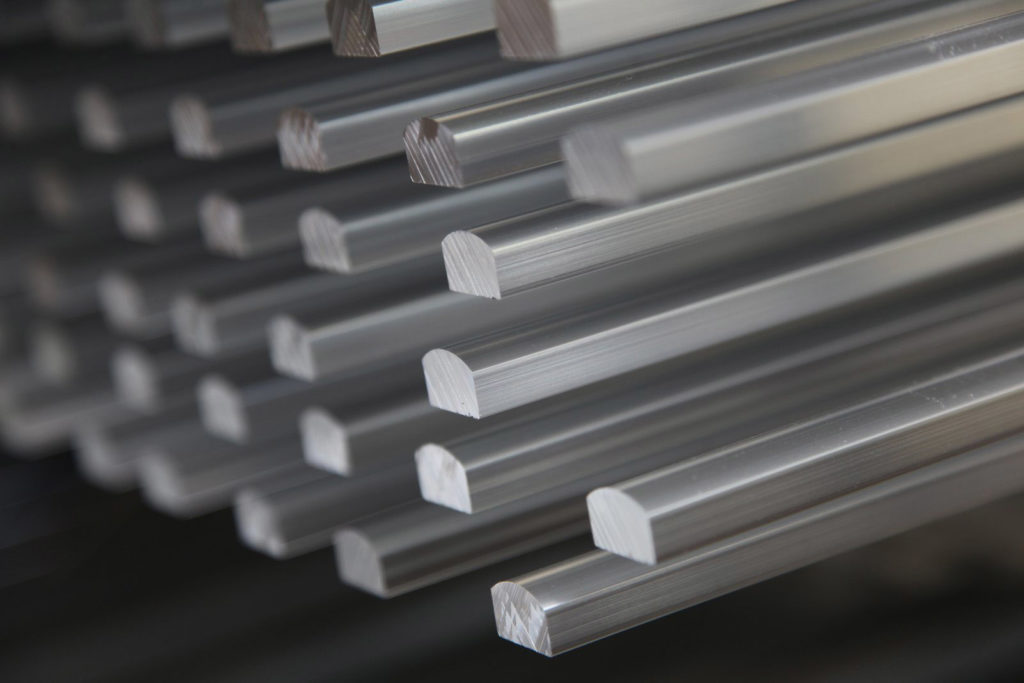

As a long-standing and trusted producer of aluminium alloys for aerospace applications, we fully meet the industry’s highest standards and stringent quality requirements. Our production processes and quality control procedures are designed specifically for this purpose.

In addition to the 2xxx and 6xxx alloy groups, we also supply 7xxx alloys in tempers required by the aerospace sector, achieving enhanced hardness and performance to withstand even the most extreme operating conditions.

Main advantages of aluminium

Trivia

Aluminium represents more than 60% of the structural weight of the Airbus A380 and up to 80% of short-range and mid-range airplanes.

Impol manufactures various parts for civil airplanes.

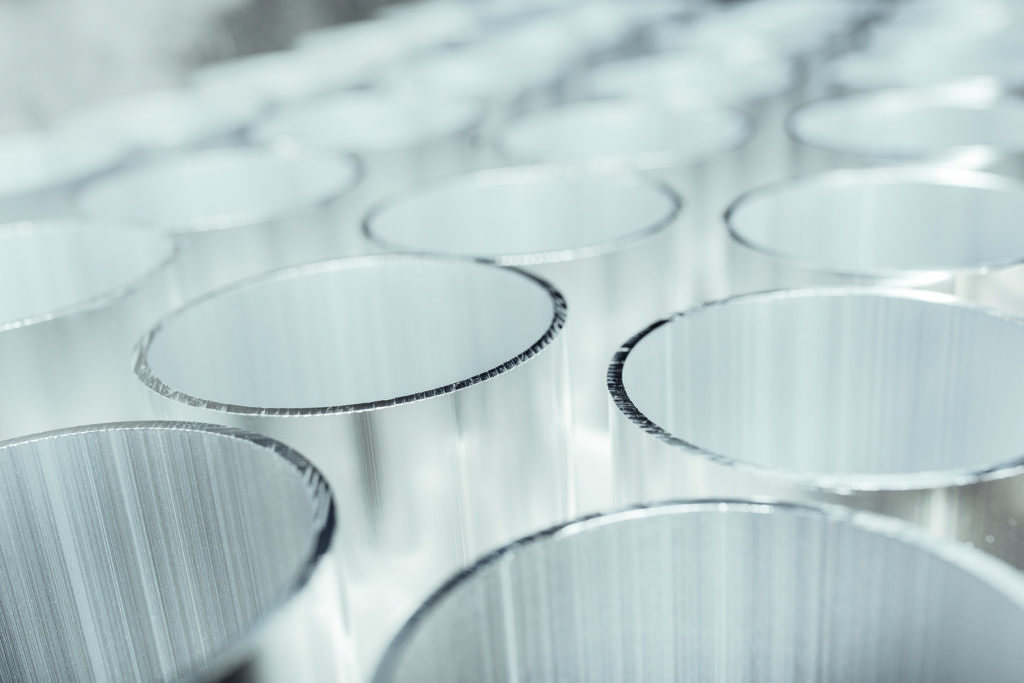

Our reputation has spread into space

Impol, the co-founder of The Centre of Excellence Space-SI, cooperates intensely with the center’s partners. The company provides the Centre with aluminium alloys and parts that can sustain extreme vibrations when satellites are launched into space, as well as thermal stress and radiation in space. Impol’s technologically advanced materials thus form parts of micro- and nanosatellite housings and individual components of these satellites, such as the X-Band Transmitter and the Star Tracker.