Aluminium has been one of the cornerstone materials of modern industry for decades. In the context of decarbonisation, energy efficiency, and technological transformation, its importance continues to grow. Thanks to its low weight, mechanical strength, durability, and suitability for circular economy models, aluminium remains a key material across a wide range of industrial sectors—today and in the future.

Why Industry Needs Materials of the Future

Industry is facing a combination of challenges: reducing carbon emissions, rising energy costs, increasing efficiency demands, and ever stricter environmental and regulatory requirements. Materials of the future must therefore enable:

-

reduced product weight and lower energy consumption,

-

long service life and operational reliability,

-

recyclability without loss of material properties,

-

compatibility with advanced manufacturing technologies.

Aluminium meets these requirements with a unique balance of properties, which explains its long-term strategic role in industrial development.

Key Properties That Put Aluminium at the Forefront

Low Weight and High Strength-to-Weight Ratio

Aluminium is approximately three times lighter than steel, while modern aluminium alloys can achieve high mechanical strength. This is particularly important in industries where weight reduction directly improves energy efficiency, such as:

-

automotive manufacturing,

-

transport and logistics,

-

lightweight construction systems,

-

industrial equipment and machinery.

Durability and Corrosion Resistance

A natural oxide layer provides aluminium with excellent corrosion resistance, even in demanding environments. This results in lower maintenance requirements, longer product lifetimes, and reduced total cost of ownership over the entire lifecycle.

Full Recyclability

Aluminium can be recycled almost indefinitely without significant loss of mechanical or chemical properties. Recycling requires only about 5% of the energy needed for primary production, making aluminium a cornerstone material of the circular economy.

Aluminium in the Context of Sustainable Development

Sustainability is no longer an added value—it is a fundamental industrial requirement. Aluminium contributes to measurable sustainability benefits on multiple levels:

-

lower CO₂ emissions through reduced product weight,

-

energy-efficient recycling processes,

-

extended service life of products and structures,

-

design for disassembly and reuse.

In industrial practice, the use of low-carbon aluminium alloys and an increasing share of secondary aluminium are becoming standard approaches to further reduce environmental impact.

Technological Versatility of Aluminium

Aluminium is highly adaptable in terms of processing technologies. It is suitable for a wide range of manufacturing methods, including:

-

rolling,

-

extrusion,

-

casting,

-

machining,

-

advanced automated and hybrid production processes.

This versatility enables the development of complex aluminium semi-finished products tailored to specific customer requirements and end-use applications.

The Role of Aluminium in Future Industries

Automotive and Mobility

Electrification and stricter environmental standards are driving demand for lightweight materials. Aluminium enables longer driving range in electric vehicles, improved performance-to-weight ratios, and greater design flexibility.

Construction and Infrastructure

In construction, aluminium is gaining importance due to its durability, resistance, and design flexibility. It is widely used in façade systems, load-bearing structures, energy-efficient buildings, and modular solutions.

Industrial Systems and Machinery

In industrial environments, aluminium supports structural optimisation, faster assembly, higher precision, and easier maintenance of production lines and equipment.

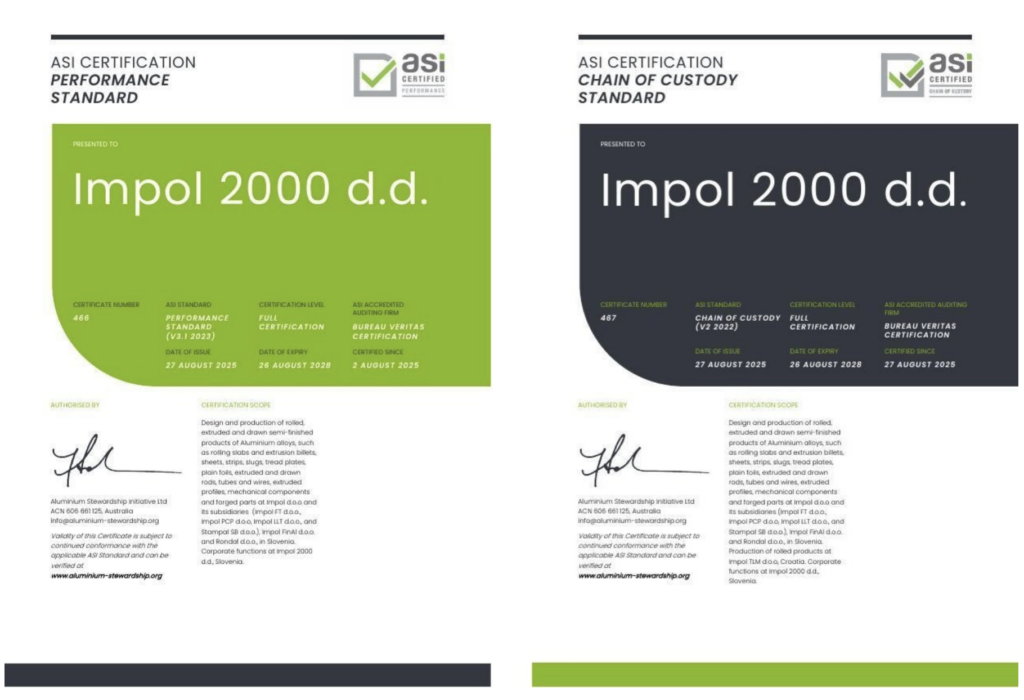

Practical Application and Development at Impol

As one of Europe’s leading producers of aluminium semi-finished products, Impol systematically develops solutions based on advanced aluminium alloys, optimised processes, and a strong sustainability focus.

In practice, this includes:

-

development of materials with enhanced mechanical properties,

-

increasing the share of recycled aluminium,

-

energy-efficient production processes,

-

close cooperation with customers in application development.

This approach ensures that aluminium remains a competitive and future-proof material, even in the face of rapid technological change.

Looking Ahead: Aluminium as a Long-Term Industrial Choice

Aluminium is not a transitional trend, but a strategic material for long-term industrial development. Its combination of technical performance, sustainability benefits, and adaptability to modern manufacturing requirements ensures its continued relevance in global industrial value chains.

For industries seeking reliable, efficient, and sustainable material solutions, aluminium remains one of the most considered long-term choices.